Wood Floor Hardness

Perception is that the harder the wood or the finish, the better. But is perception reality in the case of hardwood floors?

DEFINING WOOD HARDNESS

First, let’s explain what wood hardness is by answering the following 5 questions:

- What most influences wood hardness?

- How is wood hardness measured?

- How is the Janka Scale used?

- Why Red Oak is the reference species?

- What is a good or bad Janka rating?

What most influences wood hardness?

Wood hardness is inherent and unique to each wood species. It is characterized by the molecular structure of the species. Therefore, the natural density and hardness of a wood species cannot be changed.

How is wood hardness measured?

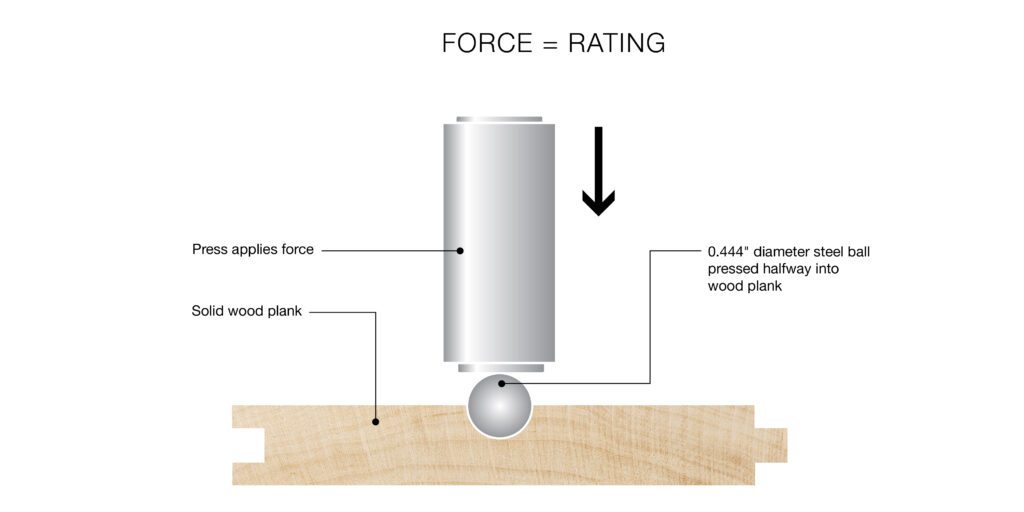

Wood species hardness is measured using the Janka Scale. The Janka Scale determines the hardness of a particular species of wood over another. The Janka Scale was invented in 1906 by Gabriel Janka, an Austrian wood researcher. It was standardized by the American Society for Testing and Materials (ASTM) in 1972. The Janka Scale measures the denting and wear resistance of a wood sample. It measures the force (in lbs.) required to embed an 11.28-mm (0.444”) steel ball to half its diameter into a wood plank.

The Janka scale applies to SOLID hardwood and softwood. It cannot be applied on ENGINEERED wood due to their assemblage of multiple woods in the same thickness.

How is the Janka Scale used?

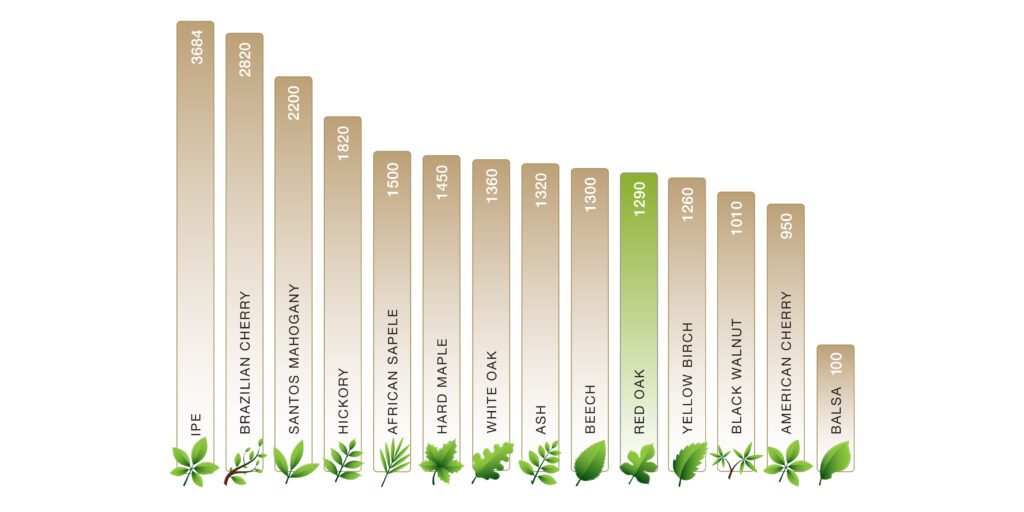

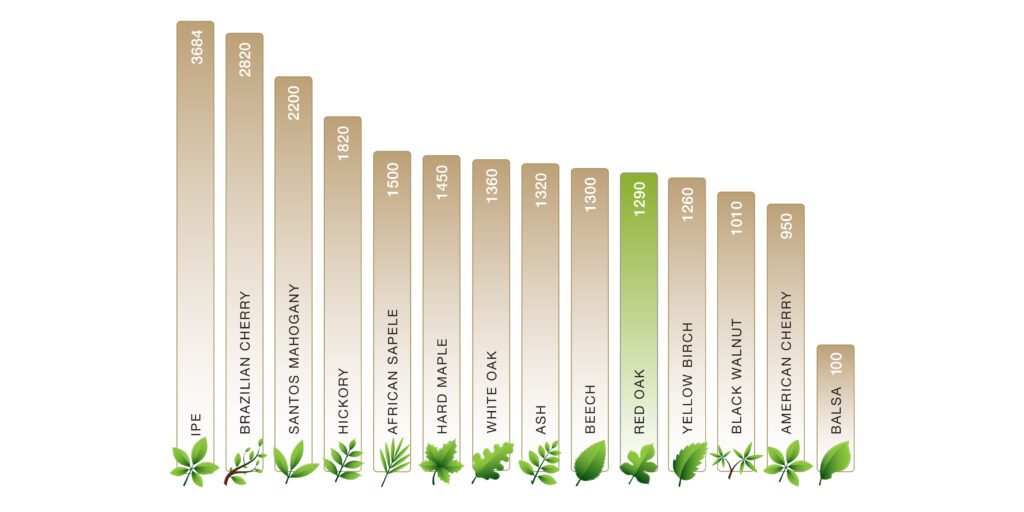

The Janka Hardness Scale runs from zero (softest) to 4,000 lbs. (hardest). Low hardness rating woods will dent and scratch most easily. At the other end, higher score ones will require more effort to nail or saw.

For example, an extremely lightweight wood such as Balsa wood -one of the lowest on the Janka scale at 100 lbs.- is typically used for crafts and could not be used for flooring. On the other hand, IPE (aka Lapacho or Brazilian Walnut) is one of the hardest woods with a score 3,684 lbs. Used when durability and high shock resistance are needed such as for decks, furniture, and flooring, it is often predrilled for screws.

Why Red Oak is the reference species?

Red Oak was chosen as the median standard because it is strong and resilient, and one of the most readily available hardwoods. With a rating of 1,290 lbs. on the Janka Scale, it is not so hard that it is difficult to saw and nail, but not so soft that it dents easily.

What is a good or bad Janka rating?

The Janka Scale does not claim that a given species of wood is better than another. When choosing wood flooring for a home, the Janka Scale rating can only provide buyers with an idea of the wood species’ strength and hardness, for example to support very heavy furniture.

All woods with a Janka rating of 950 lbs. or more, will be hard enough to be used as flooring and support normal wear of residential and light commercial use. Softwoods, such as pine, hemlock, fir, or cedar are not recommended for flooring application. All Lauzon Collection floors are made with hardwoods which highly ranked on the Janka scale.

OTHER VARIABLES TO CONSIDER

A few other additional variables will influence the resistance and hardness of a hardwood floor:

- Wood provenance

- Wood grain direction

- Texture

- Finish

Wood provenance

Growth rings are formed each year—one hard and one soft. The soft ring is formed when the tree makes its rapid growth in spring, and the hard narrow ring is formed during the slow growth in summer. Therefore, the location where the wood is harvested can make a difference in its hardness. Because these seasons’ climates vary from one region to another, the quantity of hard and soft rings will differ, thus affecting the wood harness.

Wood grain direction

The wood grains will differ based on the sawing method used. A flat cut which presents the standard molecule structure is used the Janka Scale test. An angle cut will present a more resistant molecular structure that will increase the wood hardness. As per example, if one compares the grain of a flat White Oak to the grain of a quarter sawn White Oak, the latter is the harder of the two because of the wood grain direction.

We will present more on hardwood floor sawing methods, in a later blog post.

Texture and finish

When a hardwood floor surface is brushed, the top portion of the soft wood grain (spring growth) is removed, leaving more hard wood grain (summer growth) which improve slightly the surface hardness.

Hardwood floor finish does not affect wood hardness, but it is one of the most important factors for determining the durability and ease of maintenance of any wood floor. High quality hardwood floor finishes will have good flexibility instead of being extremely hard. This flexibility allows the finish to absorb heavy impact without cracking by bending with the wood underneath. Cracks in hardwood floor finishes will cause water to seep in and cause unsightly stains.

Lauzon Collection floors offer the best UV cured finish on the market, the Titanium finish. It offers better durability, because the finish flexes with the wood instead of cracking when a heavy item falls onto it and provides remarkable protection against scuffing and chipping. Furthermore, it will not leave a chalky trace if scratched, as is the case with a standard Aluminum Oxide finish. It also makes your Lauzon Collection wood floor much more resistant to high levels of traffic over a long period of time, maintaining its luster.

In conclusion, several factors will influence the overall resistance of your hardwood floor, and maintenance and prevention will also greatly influence the look of a wood floor years after it is installed (see our maintenance guide).

To find out which Lauzon Collection wood floor best suits your needs, please feel free to browse through our Collection or contact one of our specialists at a store near you.